OUR

PRODUCTS

Our product range comprises a broad but targeted portfolio of hotmelt tapes, seam sealing tapes, polyester zips and welt solutions. They are used in the sun protection, automotive, digital printing, filter, clothing and electronics industries.

HOTMELT-TAPE

Our hotmelt adhesive tapes of the AV and AU series were specially developed for textile sun protection. They have very high stability to UV rays, remain elastic for a long time and do not discolour.

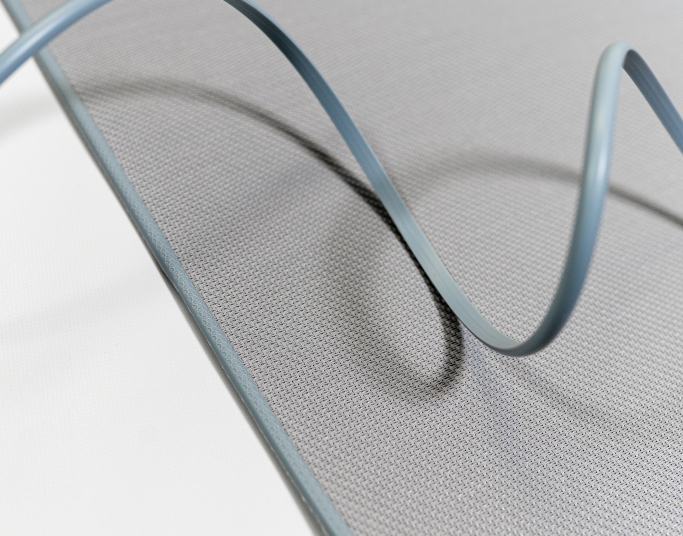

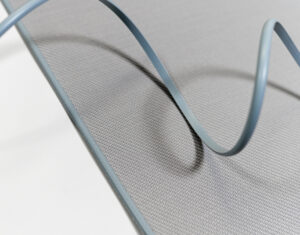

DETAILS REINFORCED

![]()

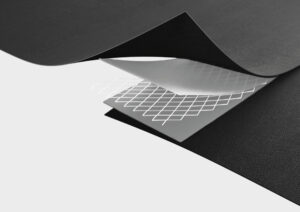

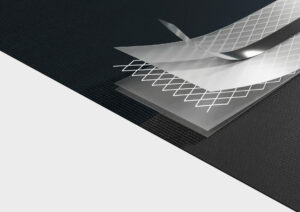

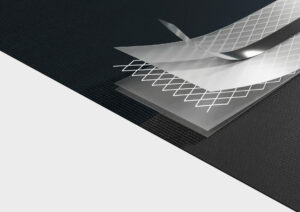

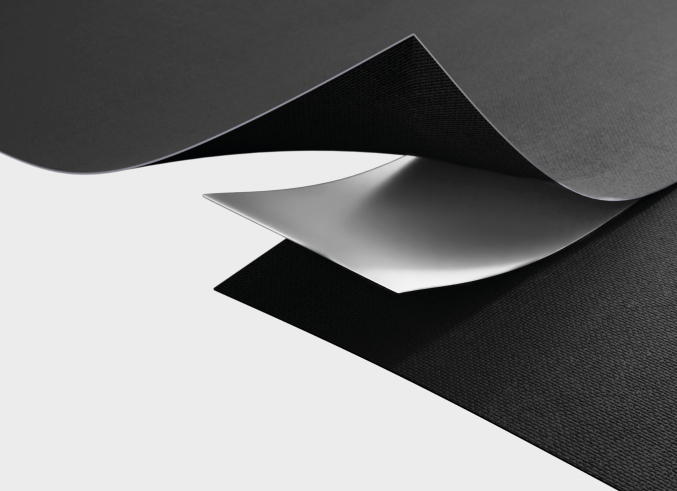

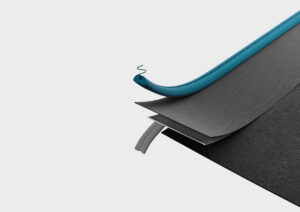

We also specially developed the AVS for bonding sunscreen fabrics, as they are highly demanding. This product is a monofilament fabric-reinforced, double-sided hotmelt tape made of polyester polymers.

The AVS reinforces acrylic and polyester fabrics as well as fabrics with a PVC or polyurethane coating in the seam area. Because the materials are subject to significant elongation during their use, this minimises overstretching and supports elastic recovery after strain is applied. When the AVS is used, the process window for processing is much larger than with glass fibre-reinforced adhesive tapes and the seam remains elastic.

Application Areas

- Conservatory awnings

- Large-sized awning fabrics

- Conventional awnings and replacement fabrics

Special features

Special features

- Easy processing in the production process

- Excellent elastic recovery

- Seam overstretching due to the roll up procedure is reduced

- Fabric pre-tensioning is omitted

- Tolerates a greater seam stretch before the seam is permanently elongated

- Enables production of an “elastic” seam

- Despite reinforcement, the seam is not thicker than a conventional sewing seam

Product variants

- 10 mm tape width

- 18 mm tape width

- 22 mm tape width

- Other widths available on request (10 mm to 1,200 mm)

Hotmelt adhesive basis:

Polyester

Properties:

reinforced

Melting point:

~110°C

Standard thickness:

220 µm

Standard width:

14 mm, 18 mm, 20 mm, 22 mm,

variable dimensions available on request

Colour:

natural

![]()

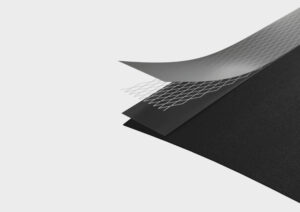

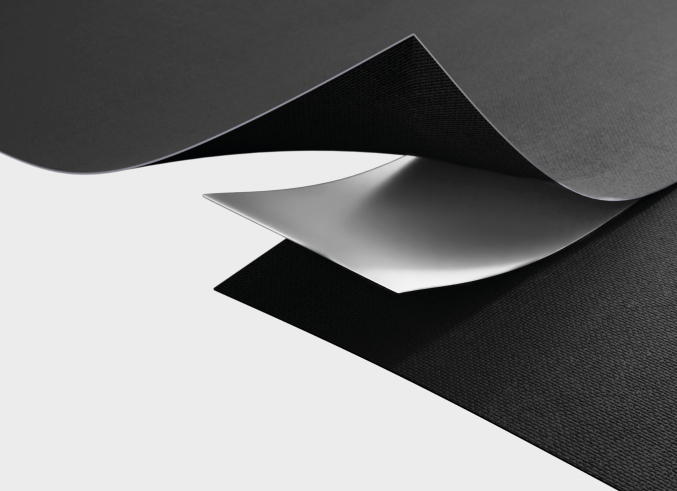

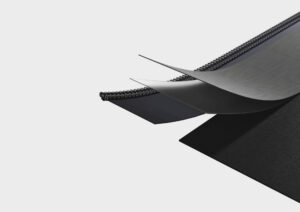

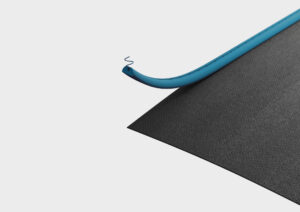

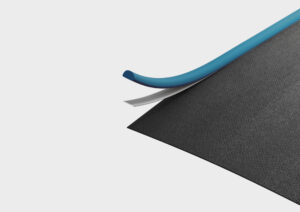

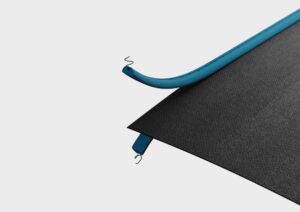

The VB is a monofilament fabric-reinforced adhesive film made of polyester polymers that we developed specially for reinforcing fabric edges.

The optional possibility to colour this hotmelt tape additionally complements its function with an aesthetic appeal and is individually designed according to your wishes. Our VB hotmelt tape is suitable for all common polyester and PVC fabrics. It can be used to reinforce and seal the edges of materials such as acrylic, polyester or PVC privacy screen fabric.

Application Areas

- Screen fabrics

- Sunscreen fabrics

- Roller blinds

- Interior sun protection

- Blackouts

Special features

Special features

-

Edge reinforcement to prevent tearing and damage

-

Easy to process

-

No fabric thickening

-

Better elastic recovery and more seam stretch than conventionally produced edge reinforcements

Product variants

-

black (RAL 9017)

-

white (RAL 9016)

-

light grey (RAL 7005)

-

dark grey (RAL 7016)

-

blue (RAL 5013)

Hotmelt adhesive basis:

Polyester

Properties:

reinforced

Melting point:

~110°C

Standard thickness:

240 µm

Standard width:

10 mm

Colour:

natural

![]()

Für anspruchsvolle Anwendungen eignet sich das VB Colored. Dies ist ein mit Monofil-Gewebe verstärkter Klebefilm aus Polyester-Polymeren, den wir speziell für die Verstärkung von Tuchkanten entwickelt haben und dessen Farbe sich individuell auf das Markisentuch anpassen lässt.

The option to colour this hotmelt tape additionally complements its function with an aesthetic appeal and is individually designed according to your wishes. Our VB Colored hotmelt tape is suitable for all common polyester and PVC fabrics. It can be used to reinforce and seal the edges of materials such as acrylic, polyester, or PVC privacy screen fabric.

Application Areas

- Screen fabrics

- Sunscreen fabrics

- Roller blinds

- Interior sun protection

- Blackouts

Special features

Special features

- No layer jumps in the joints as they occur with conventional overlapping production

- Minimal thickening at the fabric joints

- Minimized winding, compression and expansion folds

- Adapts well to the stretching and recovery of the awning fabric

Product variants

- Available in all colours

- Natural transparent edge tape to stabilize the awning fabric without silver line

- Transparent seam tape with silver center line for connecting the individual awning panels

- 21 mm tape width

- Additional UV protection thanks to a further layer of resin

Hotmelt adhesive basis:

Hotmelt adhesive basis:

Polyester

Properties:

reinforced

Melting point:

~110°C

Standard thickness:

230 µm

Standard width:

18 mm, 21 mm,

variable dimensions available on request

Colour:

variable dimensions available on request

Entwickelt wurde das UltraSeam, es ist ein Laminat, das aus Monofil-Gewebe zur Verstärkung, mehreren Lagen Klebefilm aus Polyester- Polymeren und Farbbandeinlagen besteht. Dieses Hotmelt-Tape ist wasserfest und UV-geschützt und eignet sich daher sowohl für die Ober-, als auch die Unterseite des Markisentuchs.

During processing with this product, the panels of awning fabric are bonded together joint-to-joint using the specially developed UltraSeam. UltraSeam is also optionally available as edge reinforcement and without a silver lining.

Application Areas

- Conservatory awnings

- Large-sized awning fabrics

- Conventional awnings and replacement fabrics

Special features

Special features

- No layer jumps in the joints as they occur with conventional overlapping production

- Minimal thickening at the fabric joints

- Minimized winding, compression and expansion folds

- Adapts well to the stretching and recovery of the awning fabric

Product variants

- Available in all colours.

- Natural transparent edge tape to stabilize the awning fabric without silver line

- Transparent seam tape with silver center line for connecting the individual awning panels

- 21 mm tape width

- Additional UV protection thanks to a further layer of resin

Hotmelt adhesive basis:

Polyester

Properties:

reinforced

Melting point:

~110°C

Standard thickness:

230 µm

Standard width:

18 mm, 21 mm,

variable dimensions available on request

Colour:

natural

Das UltraSeam Colored ist ein Laminat, das aus Monofil-Gewebe zur Verstärkung, mehreren Lagen Klebefilm aus Polyester- Polymeren und Farbbandeinlagen besteht, dessen Farbe sich individuell auf das Markisentuch anpassen lässt. Dieses Hotmelt-Tape ist wasserfest und UV-geschützt und eignet sich daher sowohl für die Ober- als auch die Unterseite des Markisentuchs.

Bei der Verarbeitung mit diesem Produkt werden die Stoffbahnen eines Markisentuchs mit dem speziell entwickelten Ultra- Seam Hotmelt-Tape Stoß an Stoß miteinander verklebt. Optional ist das UltraSeam Colored Hotmelt-Tape auch als Kantenverstärkung erhältlich.

Application Areas

- Conservatory awnings

- Large-sized awning fabrics

- Conventional awnings and replacement fabrics

Special features

Special features

- No layer jumps in the joints as they occur with conventional overlapping production

- Minimal thickening at the fabric joints

- Minimized winding, compression and expansion folds

- Adapts well to the stretching and recovery of the awning fabric

Product variants

- Available in all colours

- Natural transparent edge tape to stabilize the awning fabric without silver line

- Transparent seam tape with silver center line for connecting the individual awning panels

- 21 mm tape width

- Additional UV protection thanks to a further layer of resin

Hotmelt adhesive basis:

Hotmelt adhesive basis:

Polyester

Properties:

reinforced

Melting point:

~110°C

Standard thickness:

230 µm

Standard width:

18 mm, 21 mm,

variable dimensions available on request

Colour:

variable dimensions available on request

DETAILS NOT REINFORCED

![]()

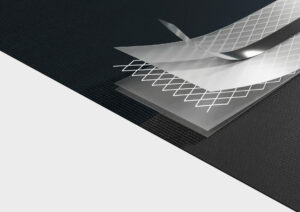

The AU is a non-reinforced, single-layer hotmelt tape made of polyester polymers. It was specially developed for bonding sunscreen fabrics.

It is mainly used for joining acrylic and polyester fabrics, but is also suitable for PVC or polyurethane-coated fabrics. The AU has a lower viscosity than conventional polyester adhesive tapes. This results in quicker and easier crosslinking between adhesive film and fabric, thus increasing the bond strength. The process window for processing is also much larger than with glass fibre-reinforced adhesive tapes and the seam remains elastic.

Application Areas

- Verklebung von Acrylstoffen, Polyester und anderen Textilien

- Für kleine bis mittelgroße Markisentücher bei innen- und außenliegendem Sonnenschutz und für Werbebanner

- Tuchkonfektion mit Seitensäumen und Varianten mit Überlappnähten

The hotmelt tape AU is a real all-rounder in

The hotmelt tape AU is a real all-rounder in

the area of sun protection applications:

Special features

- Leichtes und schnelles Eindringen des Schmelzklebefilms in das Gewebe

- Saubere Verarbeitung ohne sichtbare Durchdringung des Klebefilms

Product variants

- 10 mm tape width

- 18 mm tape width

- 20 mm tape width

- Other widths available on request

(10 mm to 1,200 mm)

(10 mm – 1200 mm)

Hotmelt adhesive basis:

Polyester

Properties:

reinforced

Melting point:

~110°C, ~130°C

Standard thickness:

80 µm, 100 µm, 130 µm, 200 µm,

variable dimensions available on request

Standard width:

14 mm, 18 mm, 20 mm,

variable dimensions available on request

Colour:

natural

![]()

Our UKF is a solvent-free, single-layer hotmelt tape made of ester-based polyurethane. This adhesive film, known as hotmelt tape, was specially developed for bonding fabrics that have a special surface structure, such as those that are coated.

Die Hauptanwendungen des UKF sind Verbindungen von Geweben aus Acryl, Polyester, PVC oder polyurethanbeschichteten Geweben. Dieses Hotmelt-Tape ist außerordentlich vielseitig einsetzbar. Durch seine hohe Viskosität penetriert das UKF in das Gewebe und führt so zu einer starken Klebeleistung.

Application Areas

- Verklebung von Acrylstoffen, Polyester und anderen Textilien

- Für kleine bis mittelgroße Markisentücher bei innen- und außenliegendem Sonnenschutz und für Werbebanner

- Tuchkonfektion mit Seitensäumen und Varianten mit Überlappnähten

The hotmelt tapes AU and UKF are our real all-rounders and differ only in the material of the adhesive film. As a result, they complement each other perfectly and are able to cover almost all textile bonding requirements.

The hotmelt tapes AU and UKF are our real all-rounders and differ only in the material of the adhesive film. As a result, they complement each other perfectly and are able to cover almost all textile bonding requirements.Special features

- Leichtes und schnelles Eindringen des Schmelzklebefilms in das Gewebe

- Saubere Verarbeitung ohne sichtbare Durchbringung des Klebefilms

Product variants

- 10 mm tape width

- 18 mm tape width

- 20 mm tape width

- Other widths available on request

(10 mm to 1,200 mm)

(10 mm – 1200 mm)

Hotmelt adhesive basis:

Polyurethane

Properties:

reinforced

Melting point:

~75°C

Standard thickness:

130 µm, other widths available on request

Standard width:

10 mm, 18 mm, 20 mm,

variable dimensions available on request

Colour:

natural

![]()

Our NKF is a solvent-free, single-layer hotmelt adhesive film based on polyamide. This adhesive film is used for bonding textiles, natural materials such as wood or leather and plastics.

Application Areas

- Textile industry

- Filter industry

Product variants

Product variants

- 1-ply hotmelt adhesive tapes

- Polyamide-based hot melt adhesive

- 0.08, 0.13, 0.18 mm hotmelt adhesive film thickness

- 10, 18 mm Tape width

- Other widths available on request

Hotmelt adhesive basis:

Polyamide

Structure:

1-ply

Melting point:

~110°C, ~140°C

Standard thickness:

80 µm, 130 µm, 180 µm,

Standard width:

10 mm, 18 mm

other widths on request

Colour:

natural

![]()

Our EKF is a solvent-free, single-layer hotmelt adhesive film based on ethylene vinyl acetate. This adhesive film is used for bonding plastics, natural materials such as wood or leather and metals.

Application Areas

- Metal industry

Product variants

- 1-ply hotmelt adhesive tapes

- Ethylene vinyl acetate-based hot melt adhesive

- 0.08, 0.10, 0.18 mm hotmelt adhesive film thickness

- 10, 18 mm Tape width

- Other widths available on request

Hotmelt adhesive basis:

Ethylen-Vinylacetat

Structure:

1-ply

Melting point:

~80°C

Standard thickness:

80 µm, 100 µm, 180 µm,

Standard width:

10 mm, 18 mm

other widths on request

Colour:

natural

SEAM SEALING

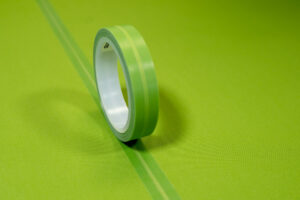

Our seam sealing tapes are designed to seal seams and thus prevent liquids or other substances from seeping through.

DETAILS

![]()

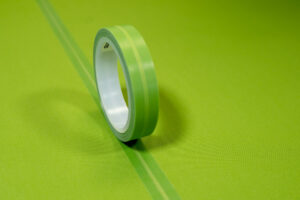

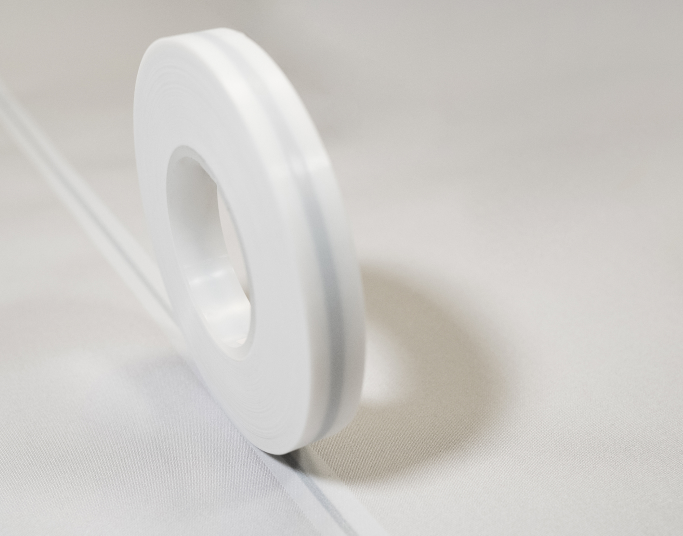

Our SST seam sealing tapes are 2- or 3-ply adhesive tapes. A hotmelt adhesive film is applied on one side of a waterproof polyurethane membrane. Depending on the type of material that the seam sealing tape is to be bonded to, different hotmelt types and melting points can be chosen. The 3-ply seam sealing tapes have an additional nylon top layer, which is available in various colours.

The seam sealing tapes are used to seal seams that should not be penetrated by liquids or other substances.

Application Areas

- Automotive industry

- Outdoor clothing and backpacks

- Skiwear

- Police and emergency service clothing

- Wasserfeste Schuhe

- Tents

Product variants

Product variants

- 2- and 3-ply seam sealing tapes

- Hotmelt adhesive on polyester, polyurethane, polyamide or EVA basis

- 0.10, 0.13, or 0.20 mm thick hotmelt adhesive film

- 16, 20, 22, or 24 mm tape width

- Other widths available on request

Hotmelt adhesive basis:

Hotmelt adhesive basis:

Polyester, Polyurethan, Polyamid, EVA

Structure:

2- oder 3-lagig

Melting point:

~75°C, ~110°C, ~130°C

Standard thickness:

100 µm, 130 µm, 200 µm,

Standard width:

16 mm, 20 mm, 22 mm, 24 mm

other widths on request

Colour:

2-ply: natural

3-ply: multiple standard colours for the nylon top layer

LATERAL GUIDES FOR

VERTICAL SYSTEMS

Our zips were specially developed for wind-proof, vertical outdoor sun protection systems. The zips are available as a single strip and can therefore be inserted directly during production. It is not necessary to separate the zip halves.

DETAILS

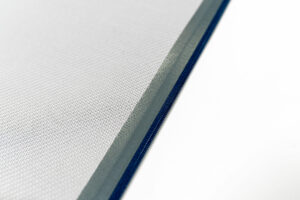

The UltraZip consists of a GtZip, i.e. a polyester zip and a bridging tape adhesive film. The bridging tape forms the connection between the zip and the fabric. The UltraZip is ideal for textiles that are guided laterally.

The UltraZip evenly stabilises laterally guided textiles to reduce the effect of the wind. In addition, our UltraSeam technology keeps the winding diameter and fabric compaction in the joining area to a minimum, as the UltraZip combines all the positive properties of the GtZip with our UltraSeam technology.

Application Areas

- Exterior and interior hangings

- Laterally guided hangings

Acrylic, screens, Soltis and many other coated fabrics

Special features

- Minimal thickening at the joint between

the zip and the fabric - Minimised wrinkles

- Ready for gluing – already wound onto bobbins ready for processing

- Various adhesive coatings

- No fabric compaction in the joining area

Product variants

- black (RAL 9017)

- white (RAL 9016)

- grey (RAL 7005)

- blue (RAL 5013)

Main component:

Main component:

Polyester spiral zip

Adhesive:

AU Polyester Hotmelt Tape

Melting point:

~110°C

Standard thickness:

180 µm / slider: 260 µm

Standard width:

21 mm

Standard colour:

black, dark blue, grey,

variable colours on request

![]()

Der GTZip ist ein Polyester-Reißverschluss- Klebefilm schluss, der ganz nach Ihren speziellen Anforderungen mit unterschiedlichen Klebefilmen individuell beschichtet werden kann. Ein Zip, unzählige Variationen!

The GTZip was specially developed for Win- StaTex outdoor sun protection systems, i.e. for wind-resistant textiles. It is available with various adhesive film coatings such as polyurethane, polyester or polyamide. The GTZip is used on the vertical outer edges of the fabric. Here, it is inserted into a profile rail as a guiding aid and thus ensures that the fabric runs smoothly continuously over the entire height.

Application Areas

- Vertical awnings

- Roller blinds

- Zip screens

Special features

Special features- Ready for gluing – already wound onto bobbins ready for processing – available in left and/or right versions

- Thanks to its high wind resistance, the fabric does not crease or tear

- Sunlight, heat and insects don’t stand a change, because everything is seamlessly joined together

- Various adhesive film coatings

- Natural transparent edge tape to stabilize the awning fabric without silver line

- Transparent seam tape with silver center line for connecting the individual awning panels

- 21 mm tape width

- Additional UV protection thanks to a further layer of resin

Product variants

- black (RAL 9017)

- white (RAL 9016)

- grey (RAL 7005)

- blue (RAL 5013)

- 16 mm tape width /

Spiralgröße 2,62 mm und 1,8 mm - 21 mm tape width /

2.62 mm spiral size

Main component:

Polyester spiral zip

Adhesive:

AU Polyester Hotmelt Tape

Melting point:

~110°C

Standard thickness:

180 µm / slider: 260 µm

Standard width:

16 mm, 20 mm

Standard colour:

black, dark blue, grey, white,

variable colours on request

![]()

TRail is an innovation for all side-seamed textiles!

With our T-Rail, we create a clean and even winding of the fabric without thickening at the edges and even without having to set down the fabric tube. The T-Rail changes its shape and always adapts to its task. When wound onto the fabric shaft, the T-Rail is as flat as the fabric. When it is unwound, the flag of the T-Rail is set up in a T-shape via a guide in the side rail and then provides the necessary lateral support for the textile in the inlet.

Application Areas

- External and internal sun shading

- Side seam guided textiles:

- Vertical or window awnings

- Conservatory awnings

- Roller blinds

- Roller blinds

- Suitable for typical technical textiles from the sun protection sector, e.g:

PVC-coated fabrics (Screen, Soltis, etc.) and PVC-free fabrics (Twilight, Starscreen, etc.)

Special features

Special features

- No thickening at the connection

TRail to fabric - Homogeneous winding

- Ready for gluing – already wound on spools ready for processing

- Significantly smaller systems can be realized

- Reduction of wrinkle formation

Main component:

Main component:

Fabric, stainless spring steel

Adhesive:

AU Polyester Hotmelt Tape

Melting point:

~110°C

Standard thickness:

0,50mm

Standard width:

4,0 mm

Standard colour:

schwarz, dunkelblau, grau, variable Farben auf Anfrage

WELTS

Our welts are primarily used for outdoor textile constructions. We are particularly proud of our new development, the NonVi welt. The invisible and innovative half welt in the area of textile sun protection.

DETAILS

![]()

The invisible and innovative welt seam in the area of textile sun protection. The welt is usually loosely inserted into the hemstitch seam. This is not the case with the NonVi Ecosˢ: the flagless half welt is sewn directly onto the edge of the fabric. The welt lies in the welt rail and possible leaks have no effect.

The now friction-locked connection disappears completely in the welt groove of the fabric shaft and/or in the existing profile and thus ensures a seamless appearance without ply jumps. The NonVi Ecos features a specially developed groove in which the thread lies in order to protect it against mechanical abrasion and other damage. This results in a lasting and strong connection between the welt and the fabric.

The NonVi Ecos consists of a PVC half welt with a groove. It is available in various sizes and can be adapted to the respective profile. By contrast, the NonVi Ecog is a bonded welt without a groove. Both products have identical properties and only differ in terms of the processing.

Application Areas

- Textile sun protection

- Display systems

- Interior and exterior sun protection

- Acrylic, screens, Soltis and other coated fabrics

- Sewn with a groove without adhesive film/ welded without a groove with adhesive film

Special features

Special features

- The continuous connection between the NonVi Ecos and the fabric ensures tension along the entire length of the fabric and thus prevents the formation of waves

- By dispensing with the traditional fabric fold, the NonVi Ecog saves material

- The seamless transition into the profile creates an appealing appearance

- Even in transmitted light, there is no optical interference due to seams or double plies of material

- Significantly easier handling during assembly as well as time and spacesaving installation

- The welt is bonded directly with the fabric edge to form a friction-locked unit with no further material used

Product variants

- 4, 6, 7, 8 mm welt width

- Other sizes available on request

- With adhesive film for joining with acrylic/polyester

- th adhesive film for joining with PVC

Main component:

Main component:

PVC half welt with groove

Properties:

bonded

Shore hardness:

85

Welt diameter:

4 mm, 6 mm, 7 mm, 8 mm

Standard colour:

grey

![]()

The invisible and innovative half welt in the area of textile sun protection. Here, the flagless welt is friction-locked with the fabric and replaces the customary hemstitch seam into which the welt must be additionally inserted.

With traditionally sewn awnings, small leaks occur at the fold due to the perforation of the needle. This is completely different with the NonVi Ecog: here, the welt lies in the welt rail and possible leaks have no effect. The welt is bonded along the edge of the fabric. The friction-locked connection disappears completely in the welt groove of the fabric shaft and/or in the existing profile and ensures a seamless appearance without ply jumps.

The NonVi Ecog is made of soft PVC that can be coated according to customer requirements. It is available in various sizes and can be adapted to the respective profile.

The NonVi Ecogᶢ and the NonVi Ecos that we present above have identical properties. They only differ in terms of the processing.

Application Areas

- Textile sun protection

- Display systems

- Interior and exterior sun protection

- Acrylic, screens, Soltis and other coated fabrics

Special features

Special features

- The continuous connection between the NonVi Ecog and the fabric ensures tension along the entire length of the fabric and thus prevents the formation of waves

- By dispensing with the traditional fabric fold, the NonVi Ecog saves material

- The seamless transition into the profile creates an appealing appearance

- Even in transmitted light, there is no optical interference due to seams or double plies of material

- Significantly easier handling during assembly as well as time and spacesaving installation

- The welt is bonded directly with the fabric edge to form a friction-locked unit with no further material used

Product variants

- 4, 6, 7, 8 mm welt width

- Other sizes available on request

- With adhesive film for joining with acrylic/polyester

- th adhesive film for joining with PVC

Main component:

PVC half welt with groove

Properties:

sewn

Shore hardness:

85

Welt diameter:

4 mm, 6 mm, 7 mm, 8 mm

Standard colour:

grey

![]()

The NonVi Flex is a composite consisting of a profile half welt with a hotmelt-coated fabric tape and a foam profile.During application, the fabric tape is bonded with the fabric edge of the hanging. Depending on the material, this can be carried out using bonding or sewing technology.

The flexible foam element enables simple, time and above all space-saving installation. The NonVi Flex does not have to be inserted longitudinally, rather it can be pushed directly into the groove in the fabric shaft from the wide side. The foam element produces a clamping effect in the fabric shaft, which is an enormous advantage, especially when replacing the fabric or performing an overhead installation.

Applications include connections between textiles and fabric shafts of all kinds. Processing can be carried out using ultrasonic or sewing technology, hot air, hot wedge, high frequency or thermal impulse.

Application Areas

- Fabric shaft side of textile sun protection and other hangings

- Interior and exterior sun protection

- Acrylic, polyester, screens, Soltis and other coated fabrics

- Bonded or sewn onto the fabric edge

Special features

Special features

- Extremely easy processing with traditional machines

- Because the NonVi Flex is joined directly with the fabric edge, which is then completely inserted into the profile, it ensures a seamless transition from the fabric to the profile, this creates an appealing appearance without shadowing due to double plies of fabric

- It is available in various sizes and suitable for virtually any profile

- By dispensing with the traditional fabric fold, the NonVi Flex saves material

Product variants

- 4, 6, 7, 8 mm welt width

- Other sizes available on request

- With adhesive film for joining with acrylic/polyester

- With adhesive film for joining with PVC

Main component:

Main component:

2 PVC half welts with fabric tape

Properties:

bonded

Shore hardness:

85

Welt diameter:

6 mm, 7 mm, 8 mm

Standard colour:

grey

![]()

The invisible and innovative welt seamin the area of textile sunprotection. The NonVi Twin consists of two half welts with a groove. The fabric is fed between the welthalves and sewn.

The NonVi Twin is highly flexible and can be used both on the fabric shaft sideand in the front profile, depending on the application.

The defined fabric tension over the entire width of the fabricprevents the fabric from “shrinking”. This creates a smooth transition that ensures a clean winding behaviour. Creases are also demonstrably minimised.

Application Areas

Front side and fabric shaft side of textile sun protection and other hangings

4-sided processing for big banners

Interior and exterior fabrics

Acrylic, screens, Soltis and other

coated fabricsSewn onto fabric with groove

Special features

Special features

- Because the NonVi Twin is bonded directly with the fabric edge, which is then completely inserted into the profile, it ensures a seamless transition from the fabric to the profile, this creates an appealing appearance without shadowing due to double plies of fabric

- Using the NonVi Twin means that the traditional fold is eliminated, thus reducing material costs

- The welt can be optimally adapted to the welt profile as it is available in various sizes

Product variants

- 4, 6, 7, 8 mm welt width

- Other sizes available on request

Main component:

2 PVC half welts with fabric tape

Properties:

bonded, sewn

Shore hardness:

85

Welt diameter:

6 mm, 7 mm, 8 mm

Standard colour:

grey

ACCESSORIES

We offer suitable accessories for our various products. From fabric locks to a digital product passport.

DETAILS

openTAG. Unser Anteil am digitalen Produktpass.

Mit openTAG sind alle wichtigen Produktinformationen stets abrufbar.

Scan the NFC/UHF chip on the textile and get immediate access to the digital product passport. The NFC chips can be attached directly to the textile or to the system. Each chip has a unique URL that links to the corresponding product website. Individual information can be securely stored in a database.

Application Areas

- All products with textile elements

- To be processed on:

- Sewing machines

- Ultrasonic gluing machines

- Heat impulse machines

- HF machines

Special features

Special features

- The service for the planned new EU Ecodesign Act

- Sofortiger Zugriff auf alle produktrelevanten Informationen

- Centralised data storage

- Unterschiedliche Zugriffslevel für Kunden, Fachhändlern und Produzenten

- Reduction of incorrect orders

- Sustainability

- Innovation as a selling point

Main component:

Main component:

NFC chip + Hotmelt Klebeschicht

Größe:

verschiedene Größen für unterschiedliche Anwendungen verfügbar

The fabric lock fixes the fabric in the lead rail and the fabric shaft without shortening the fabric overhang in relation to the centre seams. Unlike expansion anchors, the Gluetex lock fixes the side seam in the middle of the welt track.

The fabric lock offers an improvement for all awning fabrics as it prevents the formation of creases at the fabric edges and reduces the strain on the hemstitch seams in the corners. The fabric lock is made of aluminium, while the clamping screw is made of stainless steel. Fabrics can therefore be released and fixed in place again at any time.

More informations coming soon...

More informations coming soon...

Designation:

Designation:

Aluminium clamping dowel for awning hem

Properties:

Allen screw

Dimensions:

40 mm

Colour:

silver